FP06040 Tubing teflon FEP 6mm

Package 20Mts

APPLICATIONS

Beverage • Chemical Plants • Corrosives • Cryogenics • Deionized Water Transfer • Food Transfer • Lighting Covers • Laboratory • Medical • Paint Spray • Pure Water Systems • Sight Glass • Solvents • Water Sampling • Wire Insulation

What's the difference?

PTFE (Polytetrafluoroethylene) a fluorocarbon-based polymer, is a resin supplied in powdered form, which is mixed, preformed, and extruded into a paste, and then finally tubing. PTFE tubing can be used in a wide variety of applications due to its high chemical resistance, high and low temperature capability, resistance to weathering, electrical and thermal insulation, gas and vapor permeability properties and lowest coefficient of friction of any solid material. The tubing is translucent white in color.

FEP (Fluorinated Ethylene Propylene) resin is pelletized for its hot-melt extrusion process. FEP tubing is known for its gas and vapor permeability properties and excellent UV transmission ratings. While very similar in composition to PTFE, there are a few notable differences. FEP has a lower heat shrink temperature and is clearer and more flexible than PTFE.

PFA (Perfluoroalkoxy) resin, like FEP, belongs to a class of melt-processible fluoroplastics. PFA tubing is also known for its gas and vapor permeability properties and excellent UV transmission ratings. It is similar in composition to FEP but has better heat resistance and a smoother surface. It, too, is clearer and more flexible than PTFE

|

Physical Properties** |

|

|

|

|

|

PTFE |

FEP |

PFA |

|

Hardness, Shore D |

50-65 |

57-60 |

60 |

|

Tensile Strength, psi |

2000-3000 |

4000 |

4200 |

|

Elongation at Break, % |

200-450 |

400 |

400 |

|

Brittle Temperature |

<-450°F |

<-450°F |

<-450°F |

|

Max. Continuous Op. Temp. |

500°F |

400°F |

500°F |

Customers who bought this product also bought:

3 other products in the same category:

We recommend

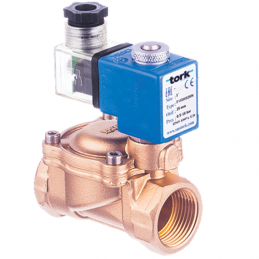

TORK Solenoid Valve 1/4,...

0 to 12 Bar, Orifice 2.5mm...

0 to 12 Bar, Orifice 2.5mm -10 a 80°C, ED100%, NBR IP65 Air,Water, Gas

Sang-A Polyurethane Tube...

6 x 4mm, Package 25, 50 y...

6 x 4mm, Package 25, 50 y 100Mts